1 min read

Quality control for medical ceramics - safety in production

‘Health is the first duty in life’, as Oscar Wilde aptly remarked. The use of technical ceramics for implants has become indispensable as a medical...

2 min read

Philipp Prüße : 03.06.2024

Technical ceramics, also known as engineering or industrial ceramics, refers to ceramic materials that have been specially developed for their superior properties and performance in industrial applications. Unlike traditional ceramics, which are often used for art or tableware, technical ceramics are characterised by their resistance to heat, wear and corrosion. It is used in numerous industries, including automotive, electronics, medical and aerospace. Technical ceramics offer a variety of benefits, including high strength, low weight and high temperature resistance. It is a key element in many high-tech products and systems.

Technical ceramics offer many advantages. It is resistant to heat and corrosion, making it ideal for extreme conditions. Its high strength and hardness ensure durability. It is also electrically insulating, making it perfect for electronic applications. Its low density makes it easy to handle. Technical ceramics are also environmentally friendly as they contain no toxic materials and are easily recyclable. These properties make technical ceramics a high-quality choice for many industries.

Technical ceramics are used in many areas due to their outstanding properties. It is indispensable in mechanical engineering as it can withstand high temperatures and pressure. It is used in electrical engineering due to its insulating properties. In medical technology, it is used in implants and prostheses as it is biocompatible. It is also used in the automotive industry for sensors and in the aerospace industry for heat shields. Its robustness and versatility make technical ceramics an essential material in many branches of industry.

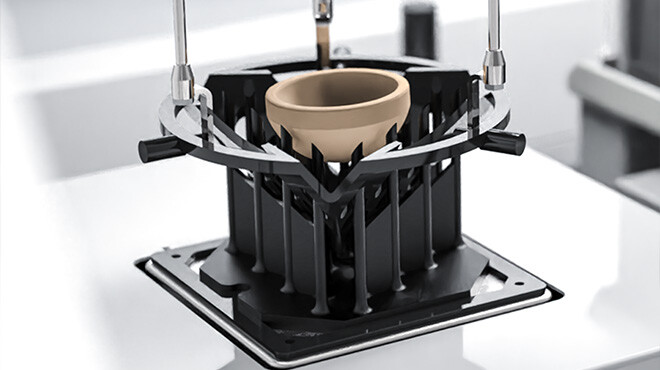

The production of technical ceramics begins with the selection and preparation of the raw materials, which are carefully mixed and ground. The resulting ‘green body’ is then moulded into its final shape by sintering at high temperatures. Processing often involves cutting, drilling and polishing the ceramic to achieve the desired properties. Technical ceramics are known for their hardness, heat resistance and chemical stability. It is used in a wide range of industries, from aerospace and automotive to medical technology. It is a fascinating material with a wide range of possibilities.

Density measurement is an important aspect in the production of industrial ceramics. Density is usually measured using Archimedes' principle. Archimedes' principle is a widely used method in which the ceramic is immersed in a liquid and the displaced volume is measured. Accurate measurement of density is crucial for quality assurance in production and makes it possible to predict the performance of the end product. And this is sometimes the biggest challenge. Typically, production is interrupted to remove a component and have its density determined by an employee on the shop floor. Unfortunately, the human factor is often the cause of measurement inaccuracies. But this is exactly what needs to be avoided. If you would like to find out how successful manufacturers of technical ceramics prevent such measurement errors, you should take a look at our article ‘Density determination of technical ceramics’.

Technical ceramics is a much sought-after material that is used in numerous industries. No wonder, as it is heat and corrosion resistant, as well as electrically insulating. This means it can withstand even the most adverse conditions - from aerospace to medical technology. But to keep it that way, accurate density measurement is essential. This is the only way to be sure that the quality is right. Innovative solutions such as fully automatic density measurement help to carry out precise measurements that are not only efficient, but also improve production and trim the ceramic end products for first-class performance.

1 min read

‘Health is the first duty in life’, as Oscar Wilde aptly remarked. The use of technical ceramics for implants has become indispensable as a medical...

What you can expect here: INTRODUCTION PRESS PARAMETERISATION PREDICTION OF SHRINKAGE BEHAVIOUR AUTOMATED DENSITY DETERMINATION CONCLUSION ...

What awaits you here: INTRODUCTION THE IMPORTANCE OF DENSITY DISTRIBUTION IN THE MIM PROCESS ARCHIMEDEAN DENSITY MEASUREMENT: BASICS AND CHALLENGES ...