Precise & traceable measurement results

Repeatable and traceable green density (up to 0.001 g/cm³)

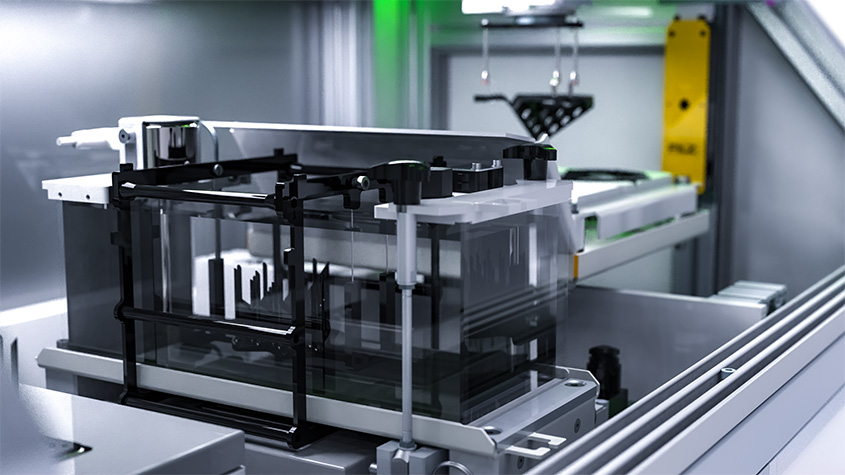

The "Dimensionics Density" density platform is a metrological system that has been developed for the fast and highly accurate density determination of components

and has a special significance in the analysis of green parts.

The density is determined with an accuracy of up to 0.001 g/cm³. This is achieved by combining the proven Archimedean principle with state-of-the-art automation technology and laboratory-standard precision scales.

The measuring process is fully automatic after the samples have been placed in the universal component carriers. During the measuring process, the system collects all environmental factors that have to be taken into account for the density determination. This makes it possible to achieve accuracies in density determination that are usually not realisable in an industrial production environment.

The density of the test object is determined by weighing in two different media. The first measurement is usually performed in air, the second measurement in a defined liquid medium with a known density.

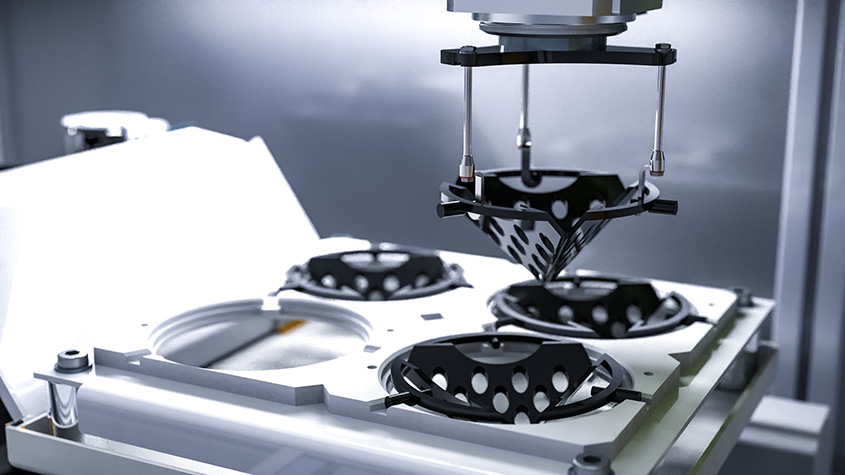

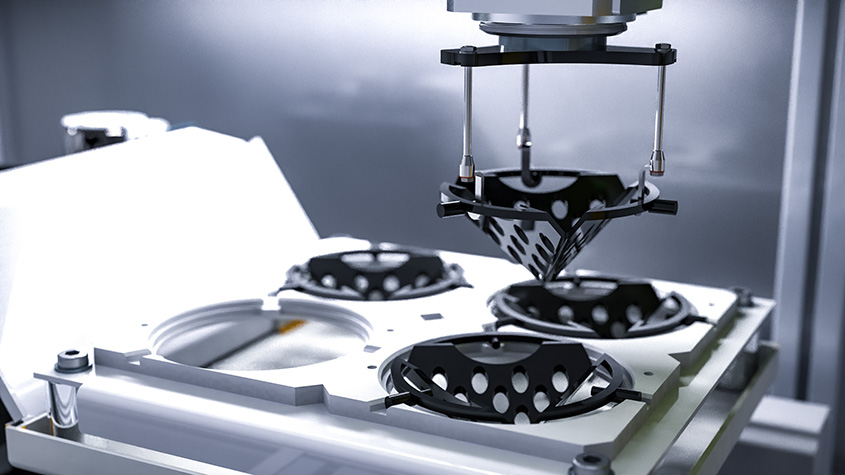

Decisive for the accuracy of the result is the positioning on the scale. Deviations from the centre of mass and resulting off-centre measurements of the component lead to strong deviations.

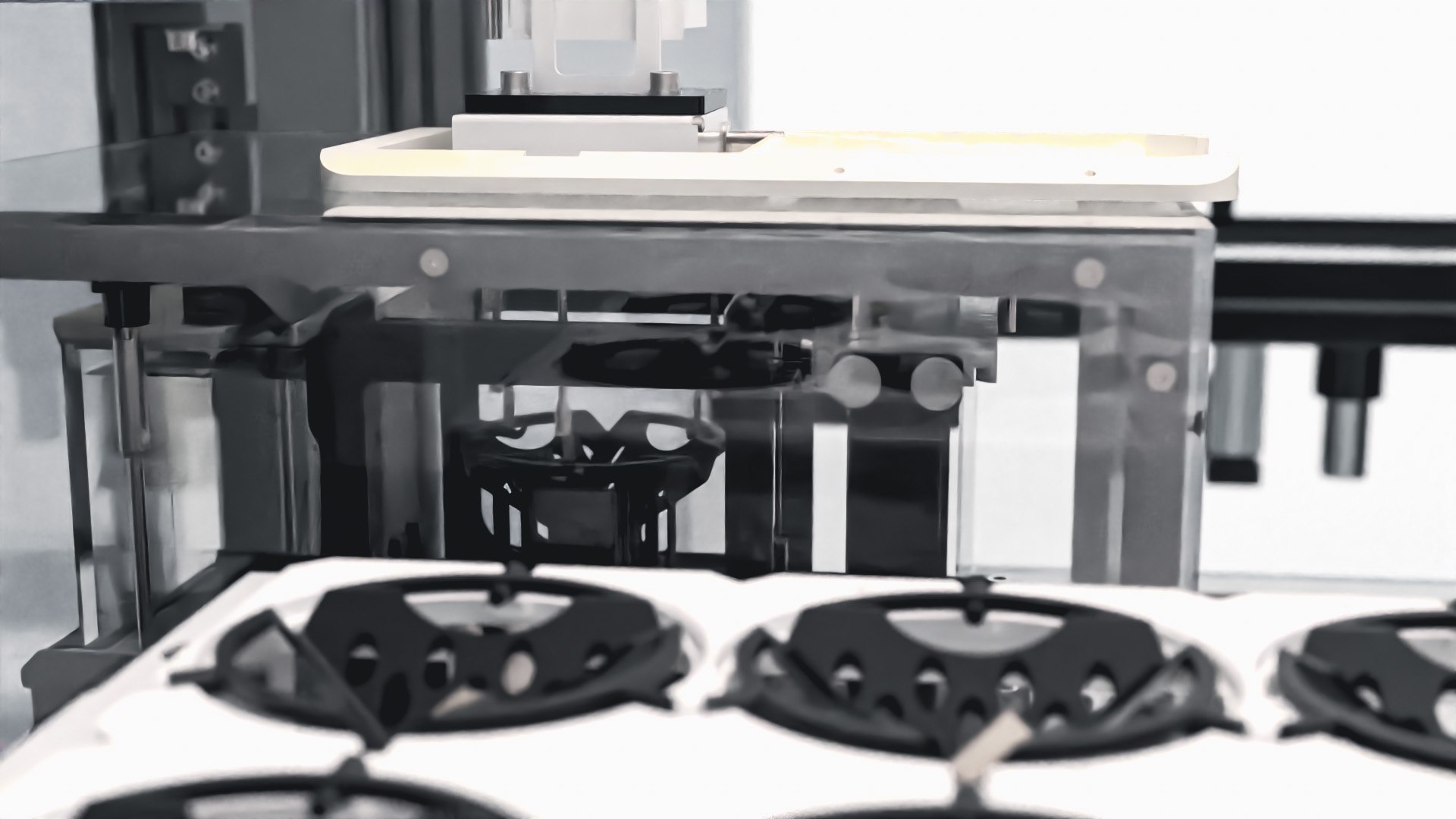

To counteract this problem and ensure repeatability of measurements, Dimensionics Density offers specially developed inserts for the universal component carriers for each type of component. These are adapted to the workpiece to be inspected and can be integrated manually without much effort.

With a cycle time of less than 2 minutes per component and the possibility of inspecting up to 18 components simultaneously in one inspection process as standard, the density platform offers the user the possibility of optimising manufacturing processes and making them more efficient.

The automation of the process also makes it possible to inspect components for density that do not show repeatable results through manual procedures. For example, green parts can be precisely examined with regard to their density.

Our Dimensionics Density platform offers numerous advantages for use in powder metallurgical manufacturing and enables the user to

to design their manufacturing processes safely and effectively.

Repeatable and traceable green density (up to 0.001 g/cm³)

Reduction of machine downtimes through density determination in less than 2 minutes

The sealing platform is designed for use directly in the production environment

Density can be integrated into existing processes and adapted through numerous extensions

Through the integration in the production you can parameterise your processes directly and immediately

Dimensionics Density supports you from the initial idea, through design to on-site commissioning. But we also support you as a partner.