Why is the density determination ...

... of molded components crucial for your manufacturing process?

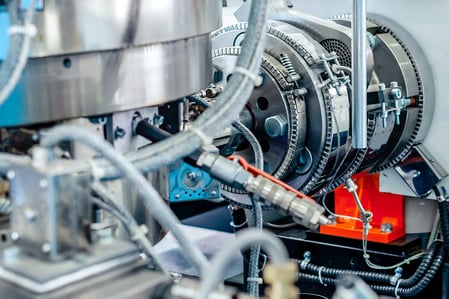

Density in the MIM/CIM sector

The decisive factor for the quality of injection-molded components is the constant density distribution over the entire green part.

Importance of density for sprayed CONSTRUCTION PARTS

Uneven distribution causes uneven shrinkage behavior, resulting in warped and out-of-gauge components. In order to evaluate the quality of the component, components are usually inspected by specialists in a manual process.

For this purpose, green parts are produced with a specific set of parameters and then debinded and sintered before they can be examined in more detail. Through an iterative trial-and-error process, one optimizes the injection parameters for each individual mold. This is done with the aid of theoretical calculations and historical data, but in general it is a costly, time- and energy-intensive, multi-stage process, as the parts must first be sintered in the furnace.

In particular, the need for trained specialists and the long reaction times to changes at the beginning of the process chain fuel the desire for a fast, automated analysis procedure.

Theory vs. practice

The inherently high accuracy of Archimedean density measurements is significantly reduced in practice by human influence. An always exact execution of the measuring steps is hardly feasible even for trained personnel.

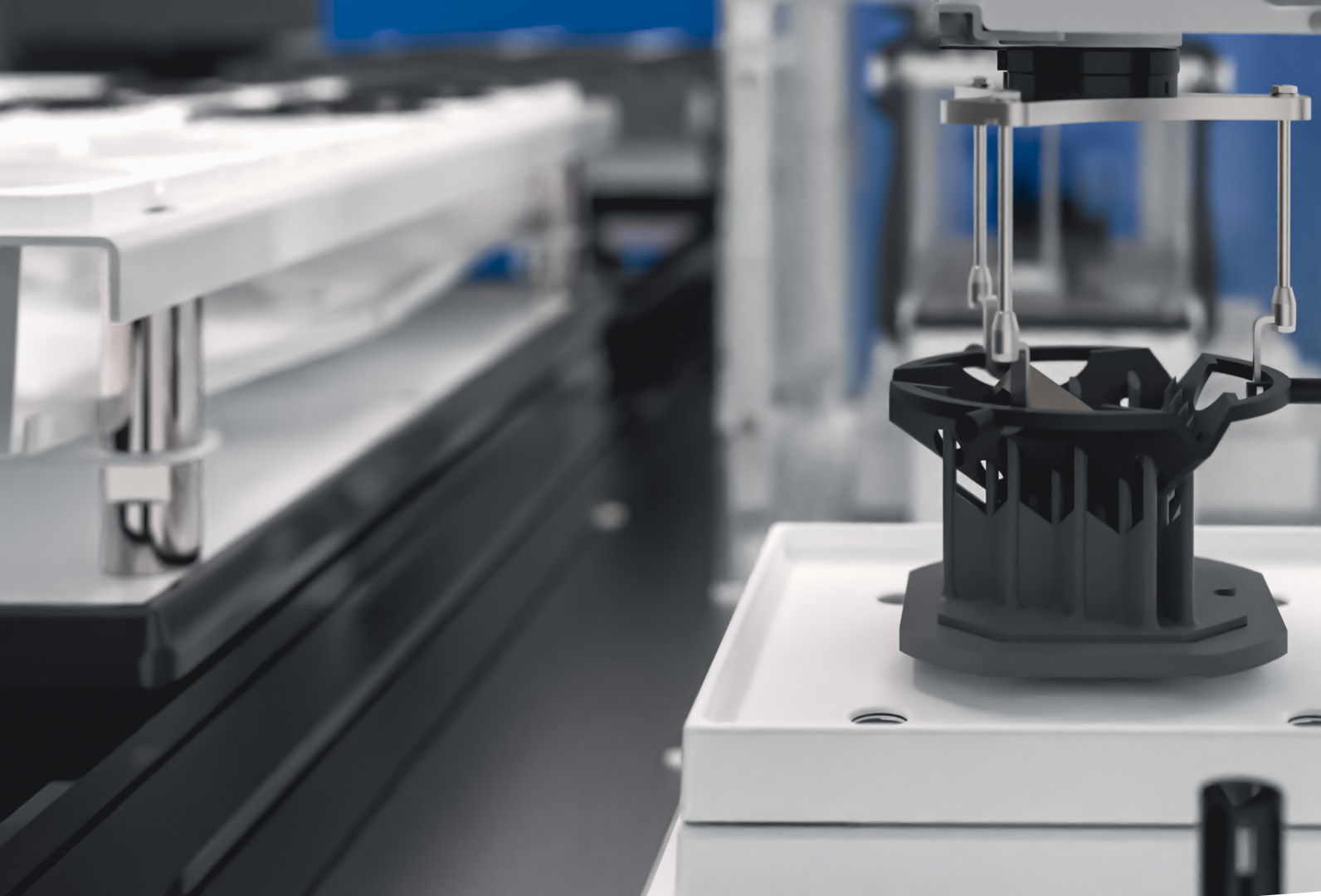

Especially not when measurements are compared by different people or over several days.The fully automated density measurement system from Dimensionics Density GmbH enables reproducible, highly accurate measurement.

The density platform as a solution

With this in mind, Dimensionics Density has developed a highly accurate, automated density determination solution that works in production environments. The technology is non-destructive and can therefore be used to check parts that meet density requirements and those that do not, quickly, accurately and cost-effectively.