Innovative, Precise, Quick

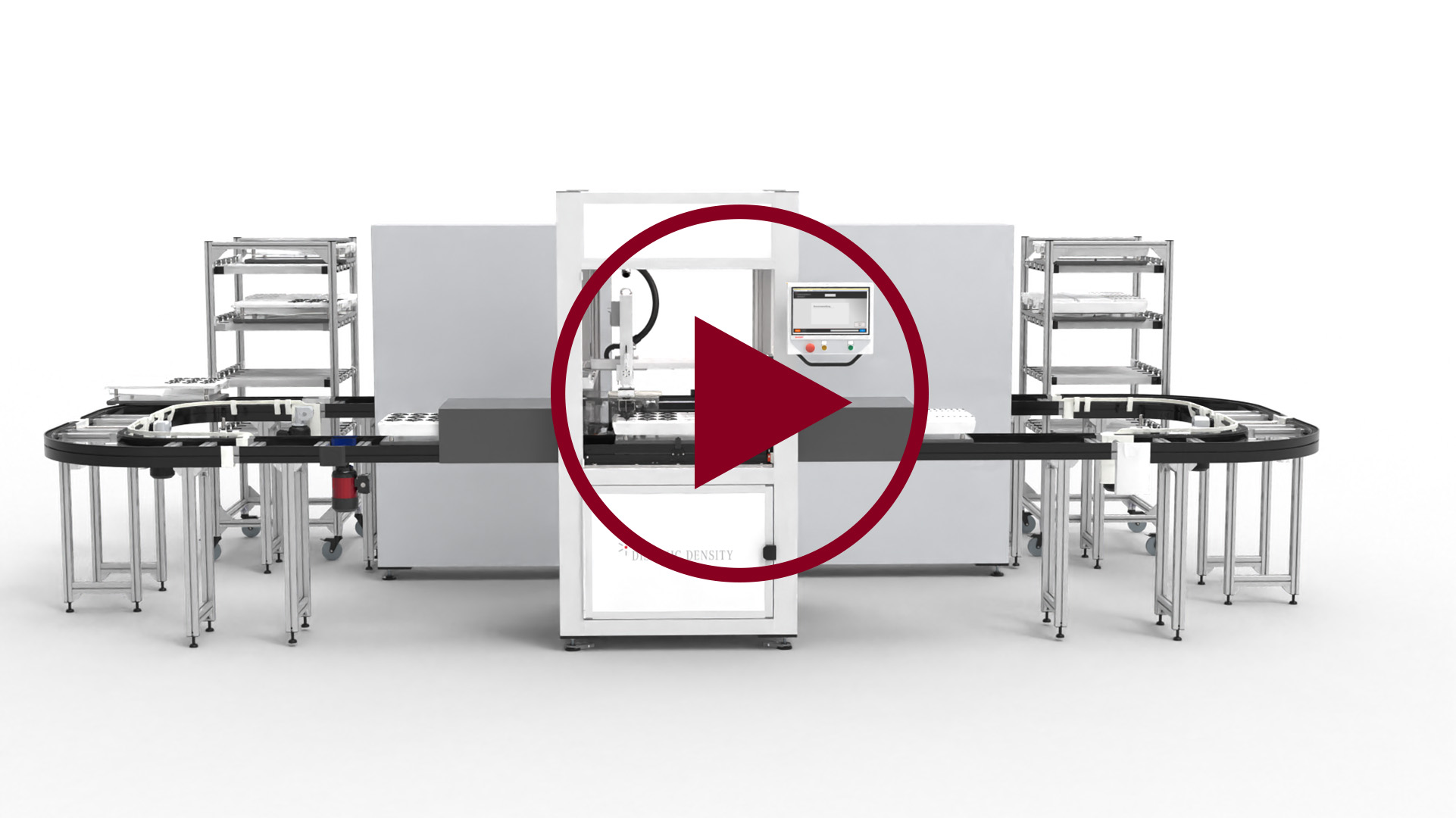

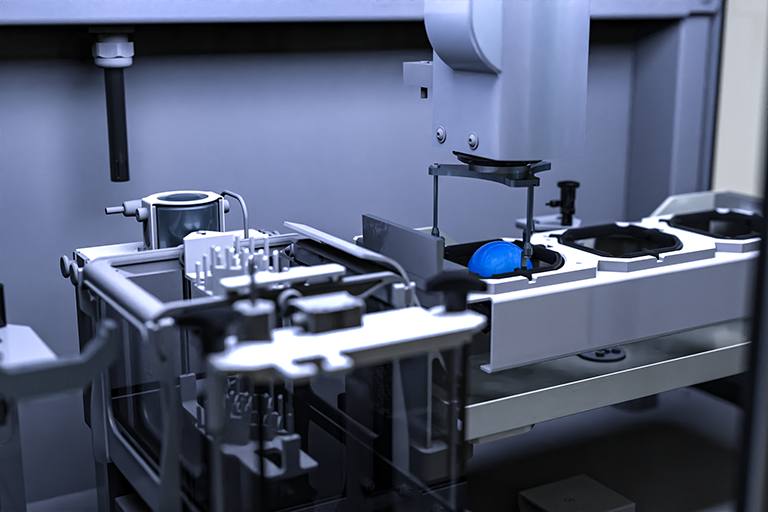

The models of the Dimensionics Density automated density platform

Density platform

At Dimensionics Density, we see ourselves as experts in density determination in manufacturing applications.

The density platform is more than just a system for optimizing your processes. It is a solution for more profitability in many industries.

More than density determination

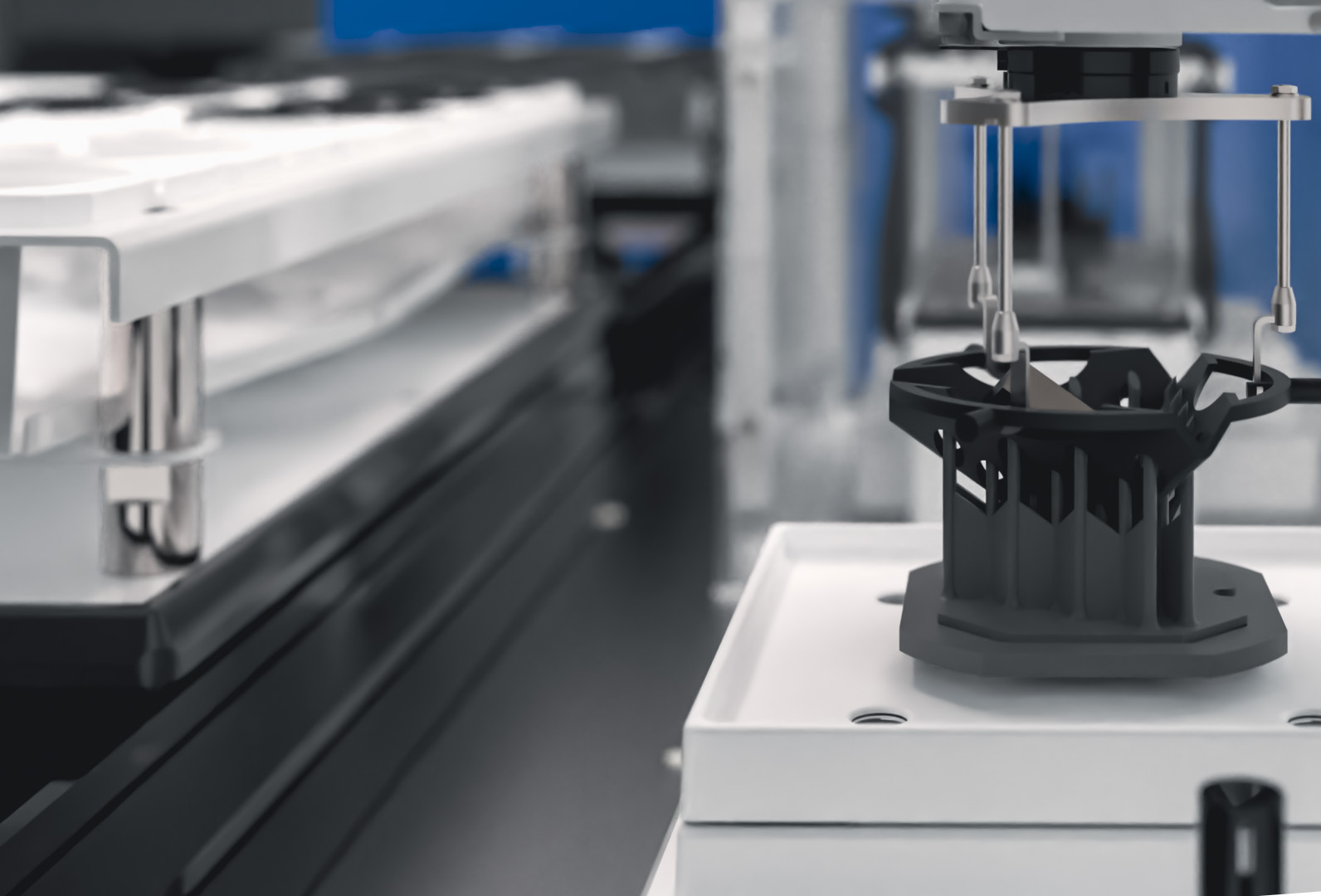

The system is based on the classical Archimedean principle. However, thanks to state-of-the-art technology and the automation of the process, Dimensionics Density has been able to create a platform that inherits the common problems of manual density tuning. The wide range of applications has produced a multitude of models. What unites all variants, however, is the high reliability, the innovative basic idea and the maximum precision for which Dimensionics Density stands.

We make density measurable

Dimensionics Density

The models at a glance

The diversity of applications is also reflected in the variance of the Dimensionics Density Platform models. Each model is optimised for a specific application or a defined process variable. All systems can be individually adapted in consultation with the customer to ensure optimal integration into the production process.

DIMENSIONICS DENSITY XS

| Parts per measurement | 15 |

| Cycle time for one measurement | ca. 1 min |

| Measurement precision | ± 0.005 g/cm³ |

| Measurements Density < 1 g/cm³ | no |

| Measurement of complex componentse | no |

| Number of integrated scales |

1 |

| Create own measurement recipes | limited |

| Automation options |

no |

| Dust protection class IP6X | no |

| Modular software packages | limited |

| Calibration standard | no |

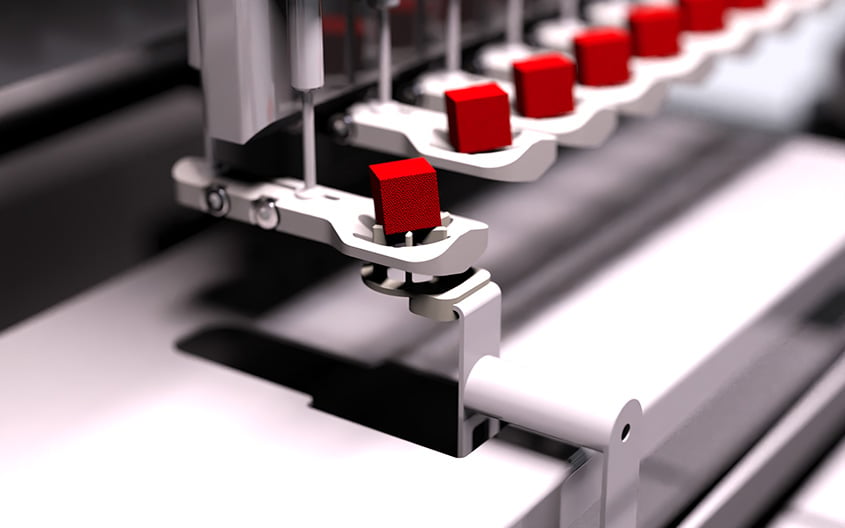

THE ADDITIVE SOLUTION

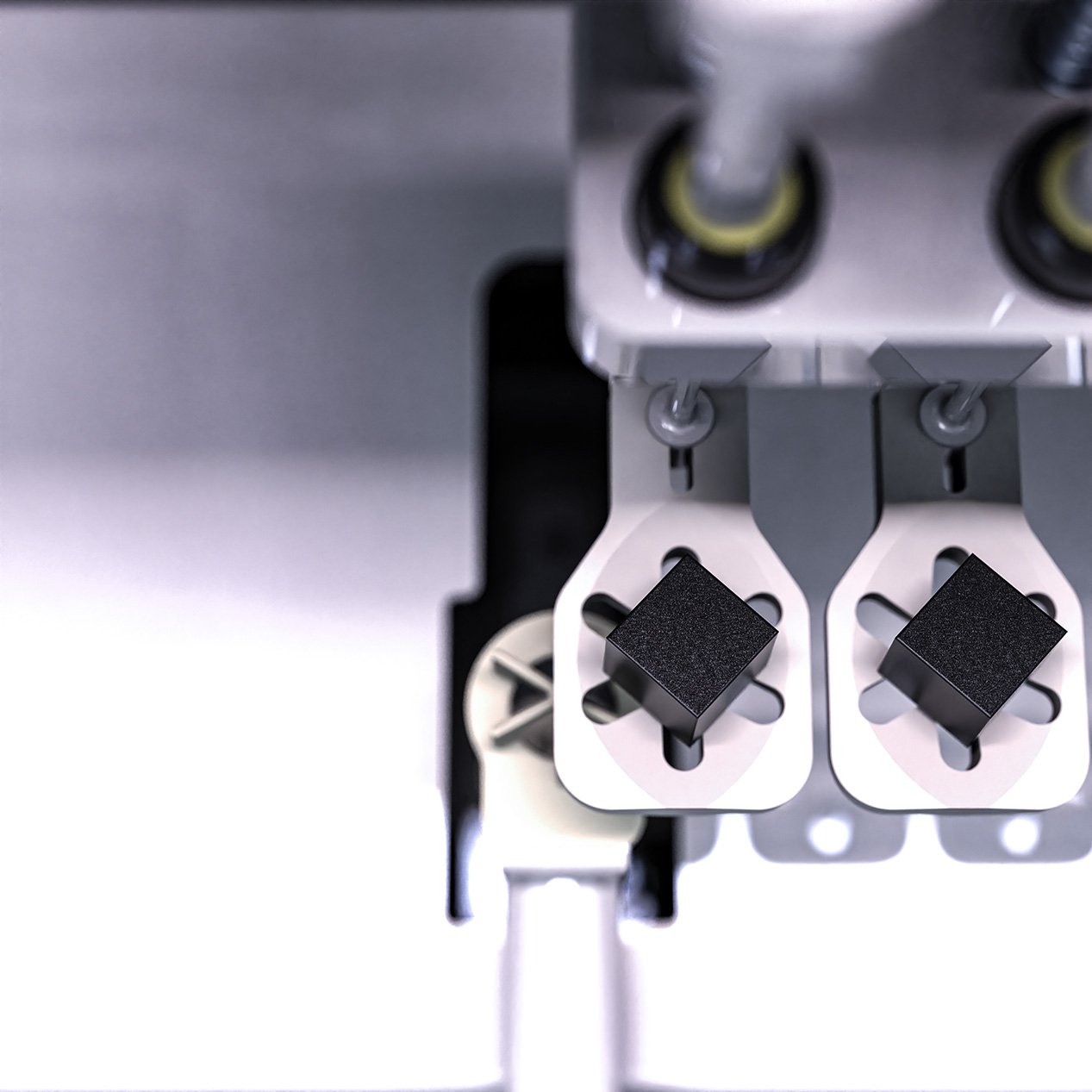

The DIMENSIONICS DENSITY XS is the smallest model in the series and is characterised by its compact design and high accuracy. To make the small installation space possible, a measuring system was developed in which both dry and wet weighing are realised by one scale. The DIMENSIONICS DENSITY XS is based on the classic design of a Jolly scale.

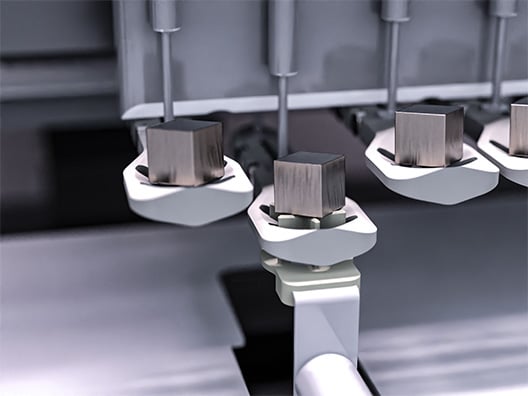

The DIMENSIONICS DENSITY XS is designed for measuring the smallest components with regular spherical and cubic shapes. After manual loading of the integrated measuring battery, it offers the possibility of fully automated testing of up to 15 samples. The measurements are transported to the measuring positions by a 2-level transport unit.

The system offers complete processing of the measured values for the QM system and can be easily linked to higher-level ERP systems. The creation of own recipes is limited compared to its big sisters.

The system is ideal for additive applications for analysing printed density cubes. These can be analysed quickly and precisely. The density obtained is compared with the stored characteristic data and, thanks to direct correlation, the porosity of the component is calculated for the worker.

DIMENSIONICS DENSITY S

| Parts per measurement | 3 |

| Cycle time for one measurement | ca. 80 s |

| Measurement precision | ± 0.001 g/cm³ |

| Measurements Density < 1 g/cm³ | limited |

| Measurement of complex componentse | yes |

| Number of integrated scales | 1 |

| Create own measurement recipes | yes |

| Automation options | no |

| Dust protection class IP6X | yes |

| Modular software packages | limited |

| Calibration standard | yes |

THE ONE-SCALE SOLUTION

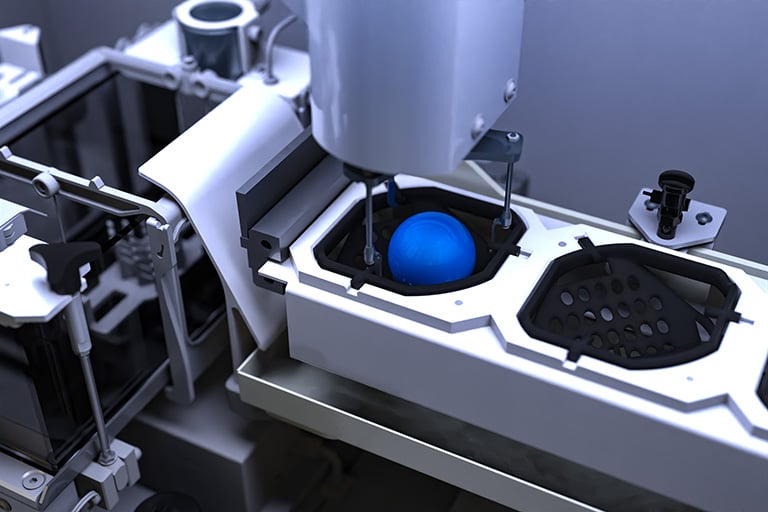

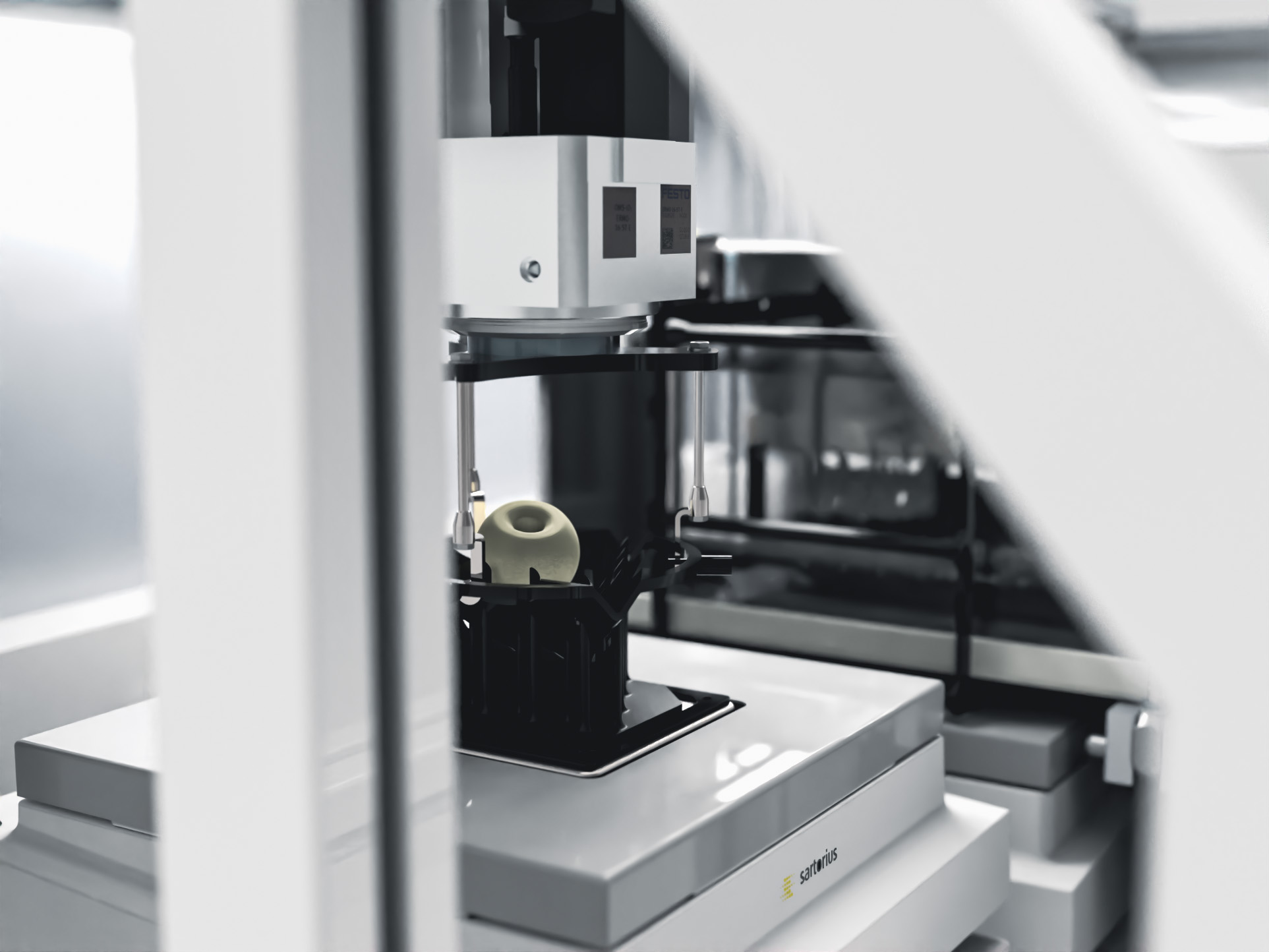

The DIMENSIONICS DENSITY S offers the perfect introduction to the world of density measurement. The innovative concept behind the Dimensionics Density S series enables a compact design and offers space for three samples per measurement cycle. Like the other models, the S series stands for high precision and low cycle times, making it ideal for companies with low production volumes or research institutes.

EA high-precision portal system and integrated sensor technology guarantee repeatable results that are also traceable thanks to a certified density standard. The system is controlled via the swivelling HMI panel and offers the user the possibility to control the entire process thanks to its user-friendly controls.

The measurement data is output on the system or can be transferred to higher-level ERP or MES systems via suitable interfaces.

The S series is an ideal entry point into quality assurance through density determination for any company. We are happy to advise you on individual enquiries.

DIMENSIONICS DENSITY M

| Parts per measurement | 4 |

| Cycle time for one measurement | ca. 1 min |

| Measurement precision | ± 0.001 g/cm³ |

| Measurements Density < 1 g/cm³ | limited |

| Measurement of complex componentse | yes |

| Number of integrated scales | 2 |

| Create own measurement recipes | yes |

| Automation options | no |

| Dust protection class IP6X | yes |

| Modular software packages | limited |

| Calibration standard | yes |

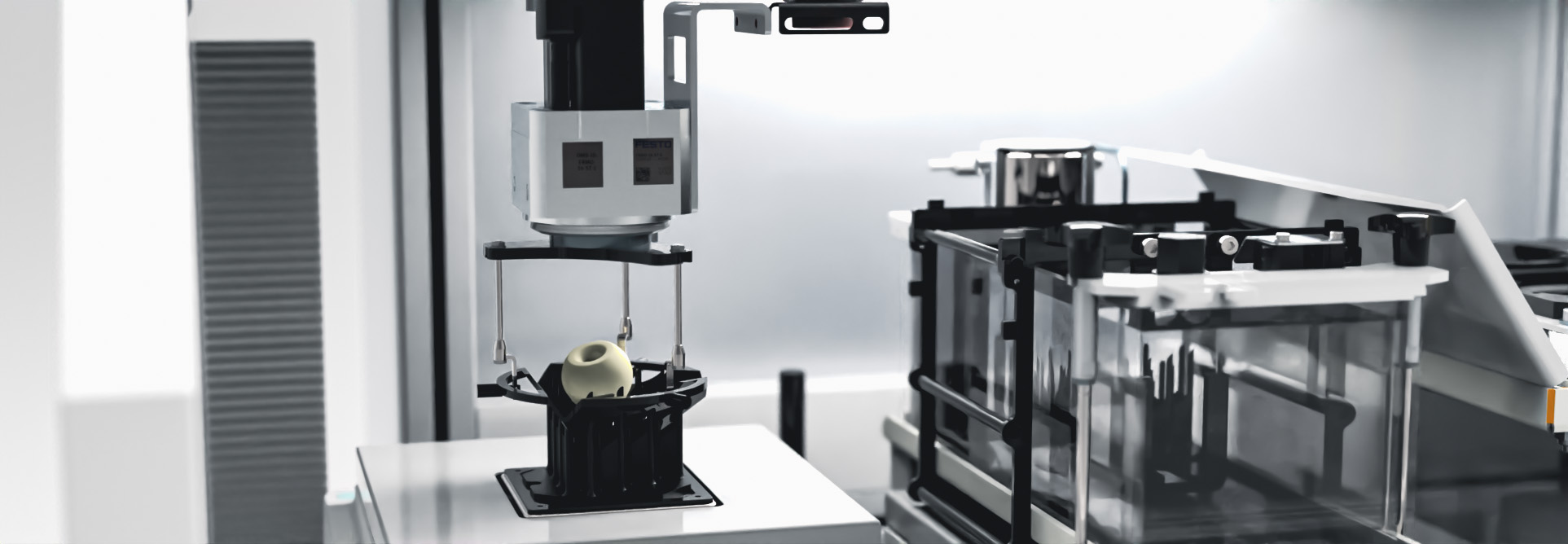

THE LABORATORY SYSTEM

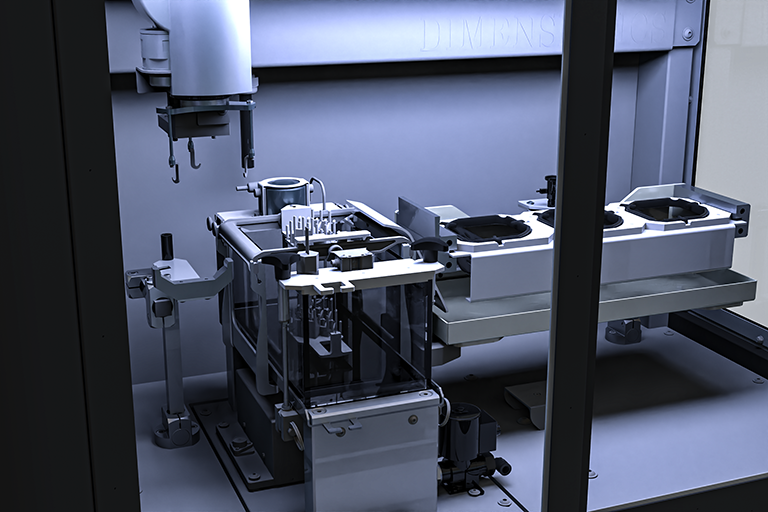

The DIMENSIONICS DENSITY M is designed for automation and support in the laboratory. With a number of 4 measurement samples in one cycle, it is designed for smaller quantities.

However, the low cycle time of approx. 1 minute per measuring cycle and the high precision provide optimum insight into your process. An installed surfactant circuit and other convenient features allow intuitive handling of the system. The integrated swivelling HMI panel, together with the user-friendly software, ensures that your employees work with maximum efficiency.

The M model series comes with a large number of integrated features. User and authorisation management is integrated, as is the feature history, which displays the characteristic values.

Due to its low number of units and the associated design customisation, it is the fastest of all models for complex components and can therefore be used optimally for fast approvals. As with the L model, the results are traceable to a state-certified density standard and are therefore ideal for companies that operate in accordance with ISO 9001.

The M model series is an ideal introduction to quality assurance through density determination for any company. We will be happy to advise you on individual enquiries.

DIMENSIONICS DENSITY L

| Parts per measurement | 18 (expandable) |

| Cycle time for one measurement | ca. 1,5 min |

| Measurement precision | ± 0.001 g/cm³ |

| Measurements Density < 1 g/cm³ | yes |

| Measurement of complex componentse | yes |

| Number of integrated scales | 2 |

| Create own measurement recipes | yes |

| Automation options | yes |

| Dust protection class IP6X | yes |

| Modular software packages | yes |

| Calibration standard | yes |

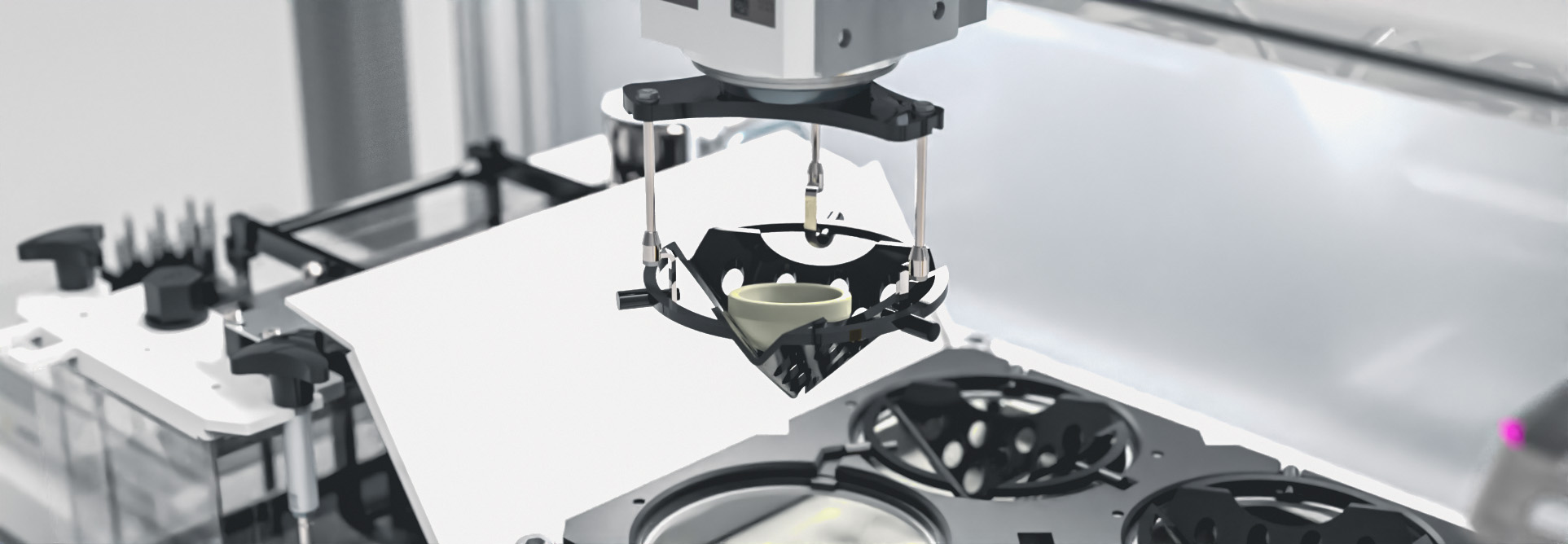

THE ALLROUNDER

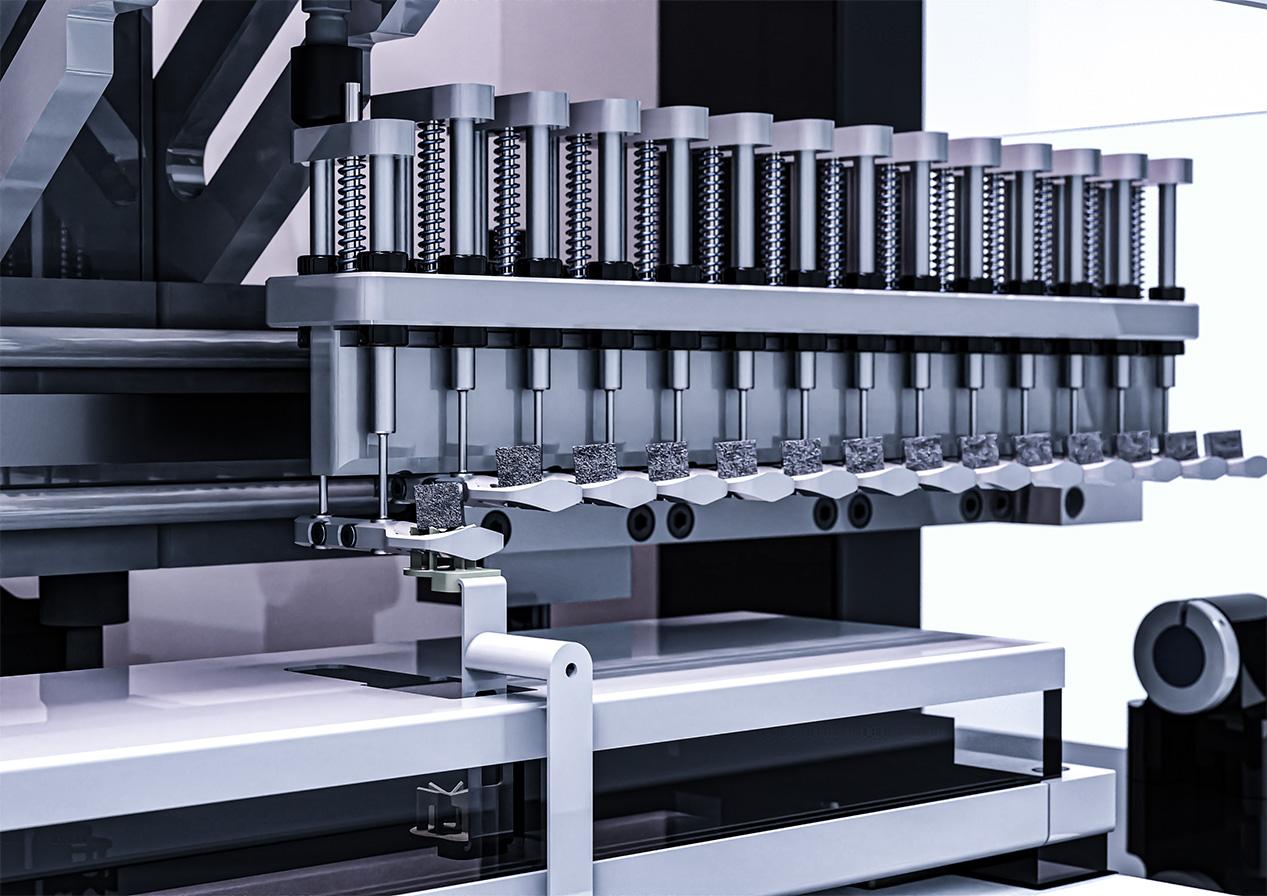

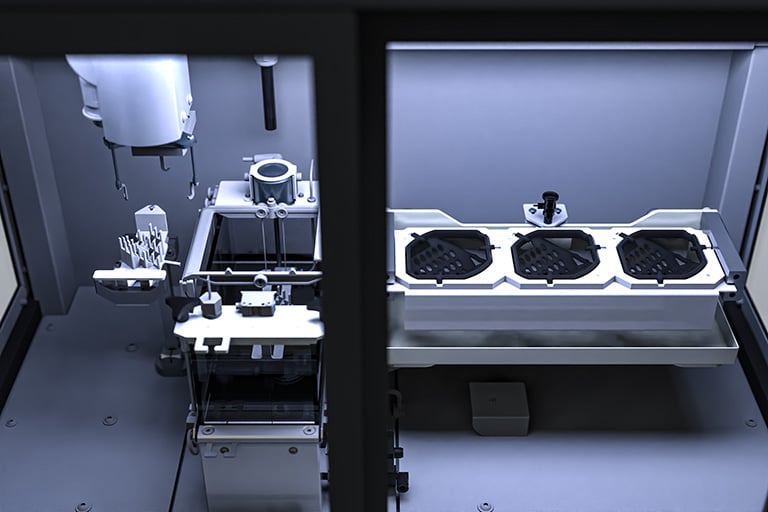

The DIMENSIONICS DENSITY L is the premium system and offers full process control & process tracking. The system can be used for high-precision testing of large quantities. As standard, the DIMENSIONICS DENSITY L offers space for up to 18 samples. However, this number can be extended at the customer's request.

A fully automated surfactant circuit guarantees trouble-free operation. The low cycle time of less than 2 minutes per measuring cycle, the high precision and the possibility of complete process integration make this model a premium product. The system offers complete dust protection. The integrated sensor system measures all relevant environmental factors and integrates their influences into the calculation of the density values.

The L model series offers the largest number of integrated features. The feature history is graphically underlaid and allows you to recognise trends in production more quickly. The parameterisation of the system and test jobs is available for all systems, but the L model series offers the greatest scope.

The model is designed for individual customisation of the software and can be tailored to customer requirements. It therefore offers the maximum adaptability of all models to your process.

In addition, the L model offers the option of complete automation with regard to upstream processes, such as the loading of component carriers, drying stations or segmentation systems. We will be happy to advise you on individual enquiries.

Extension options

We go beyond simple density determination and offer holistic solutions. Whether modular extensions (wetting of components) or process integration (production line), we support, develop and build your solution.