Density measurement meets high-tech powder pressing in Bavaria

What awaits you here: A TRIP TO KOCHEL AM SEE BACKGROUND TO DENSITY MEASUREMENT IN POWDER MOULDING INFLUENCE ON MOULDING AND QUALITY CHALLENGES AND...

‘Health is the first duty in life’, as Oscar Wilde aptly remarked. The use of technical ceramics for implants has become indispensable as a medical means of enabling many people to live an intact life. High quality and process costs are incurred in the manufacture of these implants in order to guarantee appropriate safety for the patient. The burden of proof lies with the manufacturers.

The areas of application are diverse. Bioceramics are used both in orthopaedic treatments (e.g. insertion of artificial hip joints) and in the field of dental medicine. Their advantages are just as diverse. The material is not only extremely wear-resistant and guarantees a long service life, it is also very well tolerated by patients. As these products are used in the human body, high quality standards must be met, which are guaranteed by strict regulations in the area of production. Many companies are aware of this task and are looking for new ways to optimise the process control and monitoring of their products.

Density is one of the most important properties. It provides information about possible material defects in the component. Cracks, pores and inclusions can destabilise the implant. As a result of excessive or incorrect loading, there is a risk of fracture. In order to spare the patient these risks, the manufactured components are examined. The green density is a decisive feature for the parameterisation of the final firing process in production, which determines the quality of the end product.

As a rule, manual measuring workstations in laboratories serve as the standard for density determination. Special manual density scales are used for these tests, which are operated by a laboratory technician. The measurement is based on the Archimedean principle, in which the component to be analysed is weighed in air and then in a liquid medium. This type of density determination, in which the personnel calibrate the system, carry out the measurement and document it, is time-consuming and in extreme cases can lead to downtimes in the process. This results in high costs in the final firing process, in which the kilns are not shut down in favour of the energy balance and the time required for re-firing.

The human factor also plays a decisive role in the quality of the measurement results. Incorrect parameterisation of the system or improperly executed measurements lead to significant deviations and thus ensure inaccurate or incorrect measurement results.

In order to make this process safer and more efficient, Dimensionics GmbH launched a pilot project in close cooperation with leading manufacturers of technical and medical ceramics. The common goal: an automated measuring process for 100% control. The result was the DIMENSIONICS DENSITY density platform, the world's first fully automated density scale. Not only does it fulfil the high standards of medical technology systems, it can even be operated directly in the production environment.

Analysing the density of implants poses various challenges. On the one hand, the high standards for production require maximum precision when determining the results. As all environmental parameters are monitored at all times, the system delivers highly reproducible results with a repeat accuracy of up to ± 0.001 g/cm³. The system uses sensors to monitor all relevant parameters and processes the recorded information to calculate the density.

On the other hand, the variety of different implants is a decisive hurdle for an automated system. From simple spherical and cubic shapes to more complex structures with a wide range of dimensions, it must be possible to analyse a large number of implant types. The universal component carriers developed by Dimensionics Density GmbH enable the measurement of a wide range of component shapes and sizes. The integrated laboratory scales have a large working range and can be individually selected to optimally determine the different masses of components.

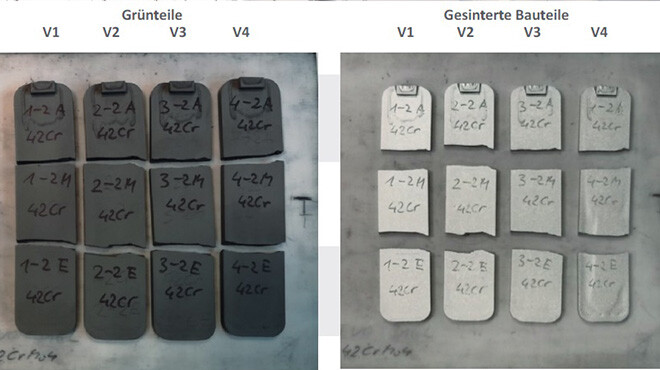

One challenge for density determination according to Archimedes' principle is determining the green density. However, this is crucial for effective production, as undesirable developments can be recognised before the final sintering process and rejects can therefore be avoided. By automating the process, the density of green compacts can also be determined with repeat accuracy.

The system offers space for 15 different types of components as standard, which can be inspected fully automatically in a single test process. The extremely short cycle time of a measurement and the high degree of automation mean that skilled labour can be relieved. This reduces costs and at the same time makes it possible to organise the production process more effectively. The high precision of the system and the automated documentation of the results enable greater transparency in the process. This is not only positive for the manufacturing company, but also allows the end consumer to enjoy their life with greater peace of mind.

What awaits you here: A TRIP TO KOCHEL AM SEE BACKGROUND TO DENSITY MEASUREMENT IN POWDER MOULDING INFLUENCE ON MOULDING AND QUALITY CHALLENGES AND...

Ceramic injection moulding (CIM) and density measurement of injection-moulded components Ceramic injection moulding is an extremely versatile...

What awaits you here: INTRODUCTION TEST SETUP AND IMPLEMENTATION RESULTS OF DENSITY MEASUREMENT OPTIMISATION OF PRODUCTION PARAMETERS CONCLUSION AND...